You are here

New Wheel Truing Machine Gets High Grades from LRV Maintenance

Heidi/ Heidi team (from left to right): Adam Solis – LRV Electromechanic/ Auxiliary Supervisor; Josh Stolz – LRV Electromechanic; Joe Lafata – LRV Electromechanic; Genevieve Coleman – LRV Supervisor; Gerd Henssen – Service Engineer w/Simmons./ Working on Heidi

Everything the LRV Maintenance Department works with is big and heavy. And that includes “Heidi” – the new $4 million, 40,000 lbs. wheel truing machine that is now responsible for re-profiling more than 1,500 wheels on our fleet of 128 light rail vehicles. “We are very excited about Heidi,” said Andy Goddard, LRV Maintenance superintendent. “Feedback from our truers has been very positive. She is in very good hands. Most importantly her operation will effectively double our capacity for wheel truing and allow us to better support our growing fleet as we move closer to our Mid-Coast expansion.” “It’s awesome,” said Joe Lafata, LRV Maintenance electromechanic. “Heidi allows us to be more efficient and it cuts with more accuracy.” Efficiency is important for the truers that work with Heidi. There are four LRV Maintenance workers that handle the workload. Goddard added that more maintenance workers will soon begin qualifying as truers. The truing process can take a while. Often times, one train can take an eight-hour shift or even longer depending on how much of the wheel needs to be trimmed.

Why is wheel truing important?

Wheel truing is important to an efficient operation because it ensures our trains run safely and smoothly on all 53 miles of track. Just like a car, the wheels on a train need to be adjusted every so often due to wear and tear – lots of miles, sweeping curves, sudden stops, debris on the tracks. So re-profiling the train wheels via truing is part of the regular long-term maintenance cycle to maintain top condition.

How it works:

Truing a Trolley wheel is the process of removing a thin layer of the wheel tread with a large “wheel truing” machine. The truing machine restores the wheel’s roundness, tread taper and flange thickness to create good ride quality and stabilized steering. Truing is important because after many miles traveled, flat spots on the Trolley wheels become apparent. It happens when the wheel locks up during an emergency stop, or when it comes into contact with oil or grease that has dripped off cars crossing the tracks. This slippery spot on the wheel can cause the train to slide on the metal rail and create a flat spot on a wheel. The flat is removed by using Heidi to take a very thin layer of steel off the wheel. Heidi has cutters on each side that can re-profile two wheels at the same time. When a Trolley’s wheel becomes too small to “wheel true” any more, its time for a replacement. Heidi helps speed up the time it takes our mechanics to do the truing, provides precision cuts and helps maximize the life of each wheel allowing MTS to be as efficient as possible.

- “Heidi” was manufactured in Germany by Hegenscheidt MFD

- Its name was given by the installer and shares the name of German supermodel Heidi Klum

- 60,000 – Miles traveled before wheel profiles are “touched up”

- Average lifespan of a Trolley wheel is 6-7 years

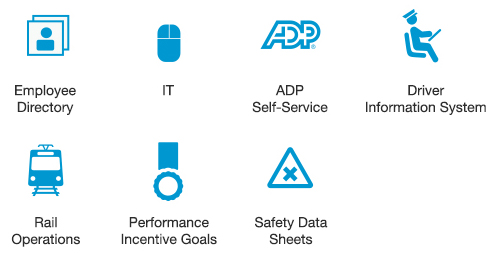

Employee Directory

Employee Directory IT Help Desk

IT Help Desk ADP Self-Service

ADP Self-Service Driver Information System

Driver Information System Bus Operations

Bus Operations Rail Operations

Rail Operations Performance Incentive Program

Performance Incentive Program Safety Data Sheets

Safety Data Sheets